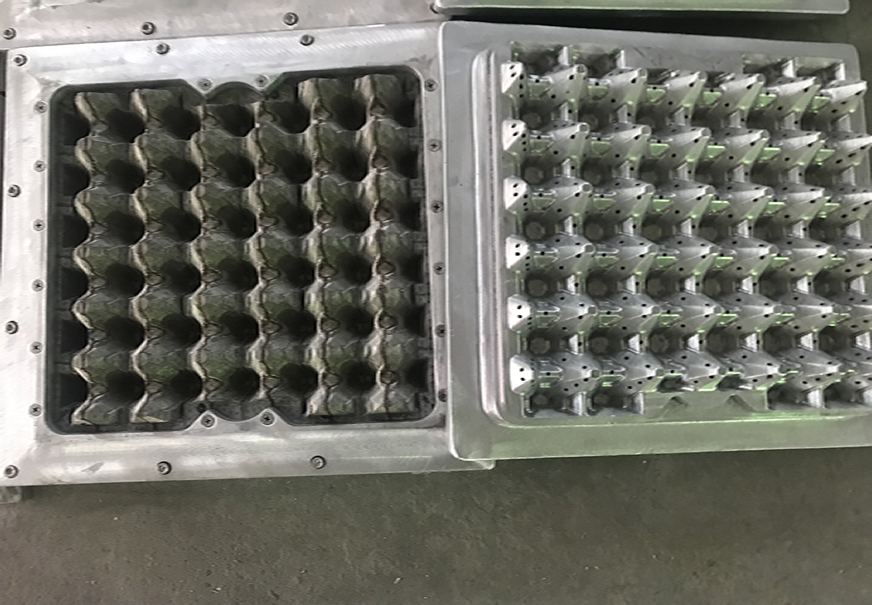

Our company can provide an absolute advantage in terms of price, the high quality mold for the egg tray directly to the factory, using CNC machining technology, can be customized according to customer needs.

Egg tray capacity

|

Capacity (pcs/Hr) | Hydrapulper | Forming machine | Drying line | Workshop size recommendation | Power requirement |

| 3000 | 2.5m³,37kw | 8sides,3pcs/unit | 20m*2.2m*4m | Length≧40m; | 180kw |

| Width≧12m | |||||

| 4000 | 3.2m³,55kw | 8sides,4pcs/unit | 22m*2.6m*4m | Length≧40m; | 260kw |

| Width≧15m | |||||

| 5000 | 3.2m³,55kw | 8sides,5pcs/unit | 22m*3m*4m | Length≧40m; | 300kw |

| Width≧18m | |||||

| 6000 | 5m³,75kw | 8sides,6pcs/unit | 22m*3.4m*4m | Length≧40m; | 380kw |

| Width≧20m | |||||

The capacity of the equipment is based on the packed egg tray with 30 dimensions 300 * 300mm and the dry weight 65g-70g

For different capacities, custom assignment according to customer needs

The size of the workshop is given as an indication and can be adjusted according to the actual size of the customer’s factory.