Machine introduction:

1. LARGE DIMENSION SCOTCH ROLL MANUFACTURING MACHINE. 2. SMALL-DIMENSIONAL SCOTCH ROLL MANUFACTURING MACHINE FOR STATIONERY This machine is panel-controlled for each of its parts, and easy to operate, three sections of electronic counter to control the length of the material accurately; The position of the label is not affected by the positioning of the tape stopper and its length can be counted in a circular fashion; High efficiency fixed point automatic switching shaft. Frequency controls speed; The blade is a round blade with air pressure drive, specializing in the production of stationery tape.

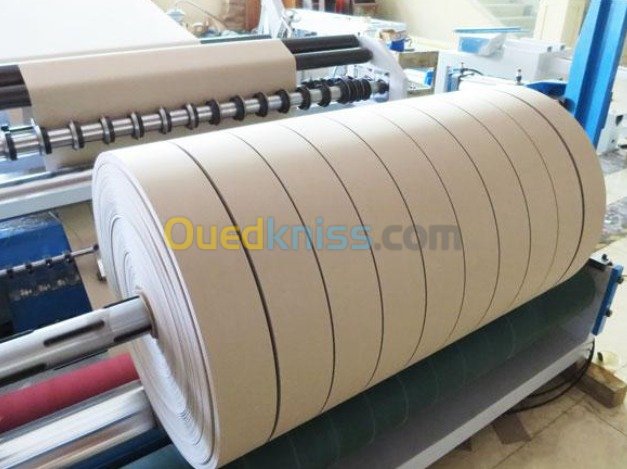

3. PAPER SPLITTING MACHINE

Suitable for slitting rewinding kraft paper, no glue paper. This machine is controlled by the panel. Easy to use. The upper and lower blade can adjust the width between 30mm and 1600mm. The paper cutting speed is high, the side material is fluid. Jumbo roll loading: no shaft loading Jumbo roll loading method: hydraulic automatic feeder Rewinding device: 3 ”air shaft Unloading method: unloading by air pressure

Main technical parameter:

- Jumbo paper roll width: 1600 mm max. 800 mm

- Diameter of jumbo paper roll: max Φ1350mm

- Unloading diameter: Max Φ1350mm

- Core diameter of jumbo paper roll: Φ76.2mm

- Diameter of unloading core: Φ76.2mm

- Paper width: 30-1600 mm

- Paper thickness: 100―600g / ㎡

- Slitting knife: 20 free sets

- Up to knife size: Φ105 × Φ70 × Φ1.5mm

- Down knife size: Φ108 × Φ80 × 30mm, This knife has a wheel, can pull out the knife

- Unloading the paper tree: an air bubble tree

- Loading jumbo paper roll type: hydraulic pressure no shaft automatic loading jumbo rollers

- Braking equipment: multi-point air brake, brake plate Φ260mm。

- Main motor: AC MOTOR 7.5kw

- Type of speed adjustment: frequency control ;

- Reduction motor: use precision reduction motor

- Machine size: 4500 × 2800 × 1500 mm

- Unloading part: use hydraulic pressure without unloading the shaft. Unloading paper from top to bottom, mixing all using hydraulic pressure , 3Kw motor.

- With a curved roller, adjust between the paper space, easy to divide

- A rubble shaftΦ216mm, a seamless steel roller, surface electroplating,

- Speed: machine speed 150m ∕ min.

- Pneumatic component: made in China

- Have an automatic count of meters.

- The side material has a wind motor.

- Paper unloading: automatic unloading at hydraulic pressure.

- Machine weight: about 4.5 tons

Other characteristics:

- The loading of the jumbo roller does not use any automatic shaft hydraulic pressure, up and down, easily move left and right, very easy loading.

- User can move the curved roll, be sure to rewind the small roll paper 100% slitting,

- Can rewind a jumbo roll once, no need to stop and tape another jumbo roll.

- The rewind paper tightens very well, surface order.

- Easy to control.

- Using the elevator, unload the sanded paper.

- MACHINE FOR MAKING PAPER CHUCKS

Main technology

- Make the core diameter: Φ20mm ~ Φ250mm

- Speed: 1-12M / min

3.Thickness: 1mm ~ 20mm

4.Length: the maximum length is 6000mm, the cutting length uses optoelectronic switch control, automatic cutting - Motor power: main motor 15KW, cutting motor 0.75kw ,

blade size Φ150X25.4X1.5mm, with 10pcs blade for free. - Control mode: main motor frequency control. Synchronous control ,

- Drive: spiral bevel gear drive

- Roll size: Φ210mm

- Cutting type: automatic cutting

- Belt type: front or reverse, no problem

- Belt: 100 × 3200 2pcs nylon round belt, 80 × 3100 4pcs.

- Paper core shaft: Φ38mm two pcs. 76.2 mm a shaft

- Coating glue type: gap type coating, circulation coating aotu of pneumatic diaphragm pump, coating on two sides.

- Automatic rotating pipe.

- Paper frame: 45º paper , each paper has tension control, make sure the tension balance.

at. The last paper and the printing paper have a single frame, a single layer of coating glue

b. Have 20 layers, 1 glue groove

vs. Printing paper glue groove - Machine weight: about 6 tons

- Main machine size: about 320m

Other characteristics:

- Put the paper frame using Z type, the maximum diameter is 1500mm, shorten the sticker time, practice loading the paper roll.

- Coating glue system uses circulation gap type coating, coating glue balance, easy-to-install paper, reduce operator touch of glue and cleaning.

- Automatic cutting of the paper core.

- The coating pipe uses the automatic rotating shaft, easy to change

- Loading the paper roll, use the hoist, automatic loading.